OMAX 5555 Series

The fast, efficient, and precise 5555 JetMachining® Center provides top performance in waterjet machining of complex parts from many materials. From simple metals to complex composites, the 4’ 7” square cutting area of the proven 5555 is ideal for rapid prototyping and just-in-time manufacturing of small to medium-sized parts. With simple fixturing and easy access to the cutting table, setup times are significantly reduced, increasing productivity and profitability.

For further information and orders, please contact 01257 248480.

Features

- Fastest cutting speeds and best precision compared to any abrasivejet in the industry and is backed by our exclusive Intelli-MAX® Software with real world cutting data

- Programmable Motorized Z-Axis with a precision OMAX MAXJET®5i Nozzle Assembly can boost cutting productivity and process efficiency

- Tilt-A-Jet® taper compensating abrasivejet cutting head (available as an option)

- Precision X-Y Axis rigidly mounted to the cutting table

- Pre-loaded linear bearings and precision ball screws

- Low maintenance, high reliability scissor-style hard plumbing

- Drive system sealed against water, dirt, and grit

- Easy operator access to the work area

- High efficiency Generation 4 EnduroMAX® pump systems available in 30, 40, or 50 hp with operating efficiencies up to 90%

- Robust and accurate design for tight tolerance cutting and reliable operation

- Rapid Water Level Control for quiet and clean submerged cutting

- Bulk Abrasive Delivery System transports garnet from the assembly’s large hopper into the Zero Downtime Hopper located on the Z-Axis

- Optional Variable Speed Solids Removal System (VS-SRS) designed for tough industrial use increases uptime through automated solids removal

- Shipped as a completely pre-assembled and factory-tested system

Benefits

- Machines a wide range of materials and thicknesses, from metals to glass

- Does not create heat-affected zones or mechanical stresses

- No tool changes and minimal fixturing reduces setup by 50% or more

- No additional water required for pump cooling

- Small, efficient footprint for minimal floorspace utilisation

- Leaves behind a satin-smooth edge, reducing secondary operations

- No noxious gases, liquid and oils used in, or caused by, the machining process

- EnduroMAX pump technology delivers the highest nozzle horsepower in the industry for faster and more efficient cutting

- Completes most work below 80 dBA

- Environmentally “green” system with quiet and clean operation with low electrical consumption

- Highly robust and reliable pump design capable of over 1000 hours between maintenance

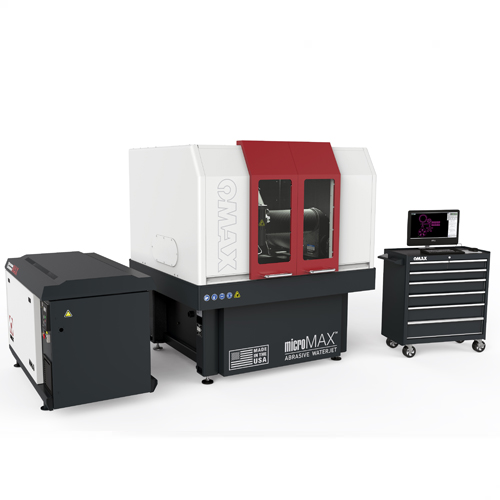

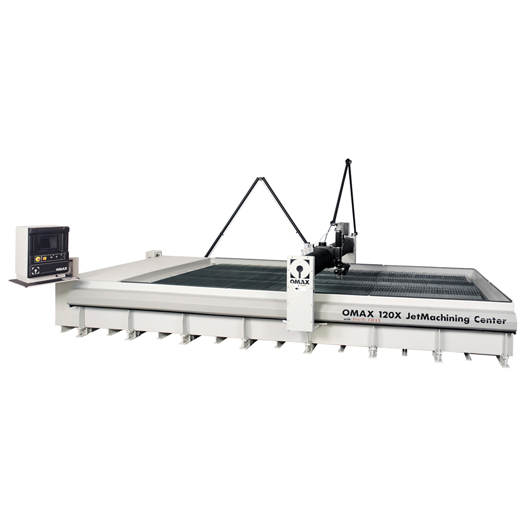

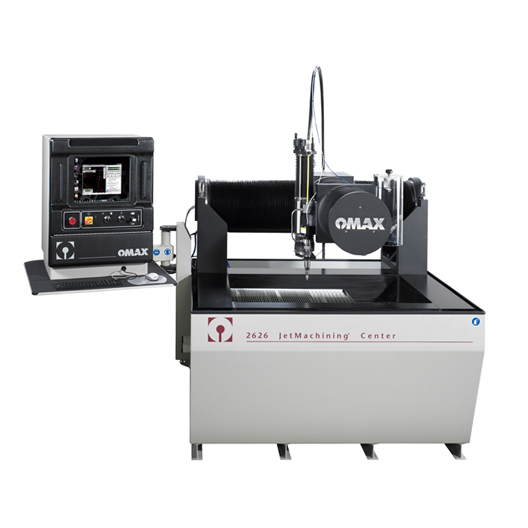

Other OMAX Machines

Customer Reviews

At Aquajet, we take immense pride in our reputation and the glowing customer reviews. We understand that a positive reputation is built on exceptional products, outstanding service and the trust and satisfaction of our valued customers.

"I have found over the years Aquajet have always given 120% in customer service. A pleasure to do business with."

Keith Webster

"Absolutely amazing service. Very quick and professional. I will definitely be using this company again."

Phil Grant

"Brilliant service from these guys. Clean cuts precision on point. Would recommend."

Rob Carnson (Source: Facebook)