Posts Tagged ‘OMAX’

Iconic Holiday Sign Made Possible With OMAX Technology

Herb Olbrich, owner of LMK Waterjet in Kenilworth, New Jersey, was asked to perform a miracle for 34th Street in late October this year. He had less than a month…

Read MoreOMAX Interactive Reference (OIR)

The most comprehensive interactive waterjet reference available, the OIR features articles, videos, tutorials, a developer’s guide, teachings on the fundamentals of abrasivejet machining, tips and techniques for faster cutting and…

Read MoreWaterjet Finds its Groove in Maker Culture

One might describe software developer Autodesk’s Workshop at Pier 9 as a traditional communal workspace. But in reality, it is a highly advanced maker space where artists, engineers, designers, architects…

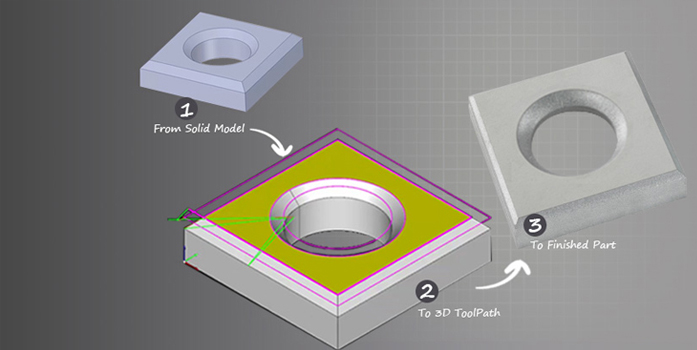

Read MorePowerful and Free OMAX Intelli-CAM

Intelli-CAM is a highly advanced computer-aided manufacturing (CAM) software program with two tools in one that can generate either 2D or 3D tool paths from 3D models. Simply import a…

Read MoreOMAX eLearning

OMAX have just introduced their new eLearning program, delivering self-paced courses to help you learn how to use your OMAX machine. OMAX Help Resources OMAX provides many sources of information…

Read MoreReverse Osmosis System

What is Reverse Osmosis? To understand reverse osmosis, you must first understand osmosis. During natural osmosis, water flows from a less concentrated solution through a semipermeable membrane to a more…

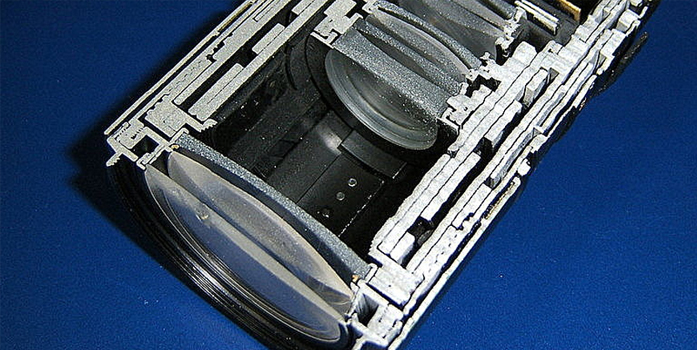

Read MoreComplementing EDM with Waterjet Cutting

Abrasive waterjet cutting and wire EDM work are the specialties of Jack’s Machine. McGrail noted that what motivated him to venture into abrasive waterjet cutting was the fact that a…

Read MoreWaterjet Flexibility Expands Production

When David Durgin of Mainly Metals from Vermont needed to expand out of the niche market he was in, he looked at new machining centers. After reviewing the benefits and…

Read MoreOMAX Unleashes Intelli-MAX® 21 At EASTEC 2015

OMAX recently expanded its Intelli-MAX Software Suite with the release of Intelli-MAX 21. The new version – with a new fourth generation cutting model – was on display at EASTEC…

Read MoreOMAX Education Package

Building tomorrow’s engineers and machinists today is essential to advancing modern manufacturing. The OMAX Education Package is designed to help your educational institution teach new students about modern abrasive waterjet…

Read More