News

What Makes OMAX Unique?

A waterjet is made up of several critical key components, such as the high pressure pump, the nozzle, and control software. OMAX designs, manufactures, and supports their waterjet systems all…

Read MoreDirect Drive Efficiency: Doing More with Less

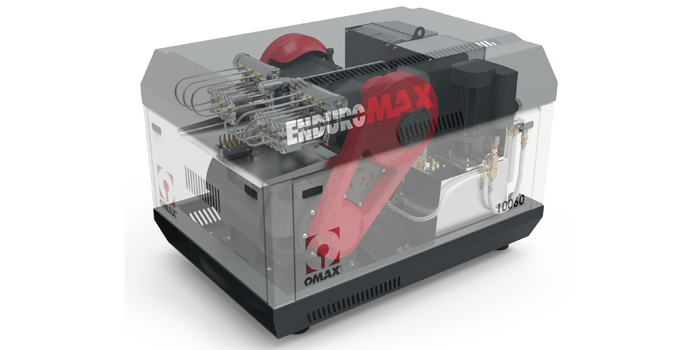

The muscle behind waterjet technology is a high-pressure pump that converts electric motor horsepower to nozzle hydraulic horsepower. The more nozzle horsepower, the faster you’ll cut. However, with two different…

Read MoreBuilt-in Cornering Strategies Improve Cutting Speed and Precision

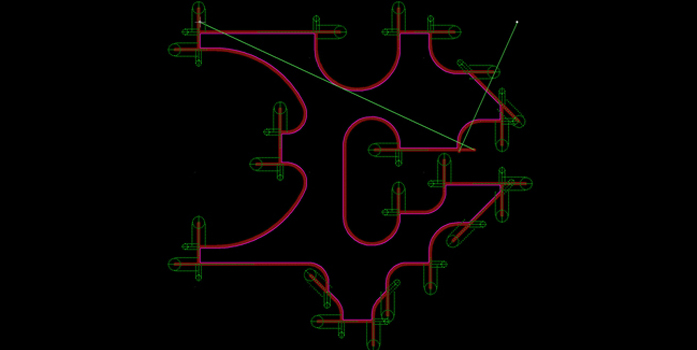

OMAX waterjet software includes a corner handling feature that analyzes all the corners in a part file and automatically sets the optimal cutting speed for each individual corner. For outside…

Read MoreWaterjet Increases Precision and Profits for Metal Cutting Service

For JACQUET Italtaglio, saying “yes” to a request for custom cut thick stainless steel parts with tight tolerances and a fast turnaround time is part of everyday operations. That’s because…

Read MoreWhat Makes OMAX Different?

OMAX develops complete waterjet systems, not just individual components. We even develop the CAD/CAM software and the motion control software for our waterjets. We’ve developed sophisticated mathematical models used in…

Read MoreWaterjet Helps Job Shop Expand

West Coast Steel Fabricators began operation in 1979 and does custom fabrication work that includes conveyors, bins, hoppers, tanks, trusses, ductwork, silos and much more. In essence, listing what products…

Read MorePerfect Piercing

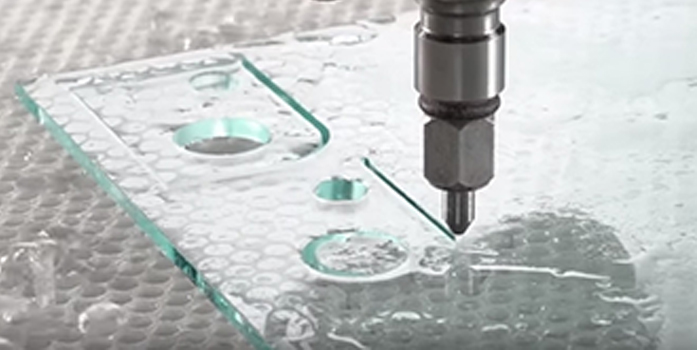

Abrasive waterjets make it easy to quickly cut precise parts from almost any material. How the machine pierces the material affects the overall production time and resource usage. Several piercing…

Read MoreReduce Machine Downtime

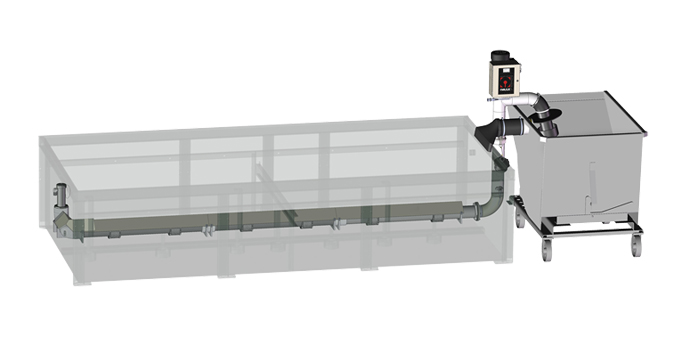

Regularly removing used abrasive and material particles from the tank is an important maintenance operation for abrasive waterjets. But shoveling out that sludge is a pain! And taking the machine…

Read More3D Waterjet Cutting Capabilities Bring More Productivity Options to Machine Shop

Abrasive waterjet systems have become increasingly more prevalent in machine shops and fabrication shops and prototyping labs over the last few decades. The cold cutting process used by waterjets has…

Read MoreWaterjet Finds its Groove in Maker Space

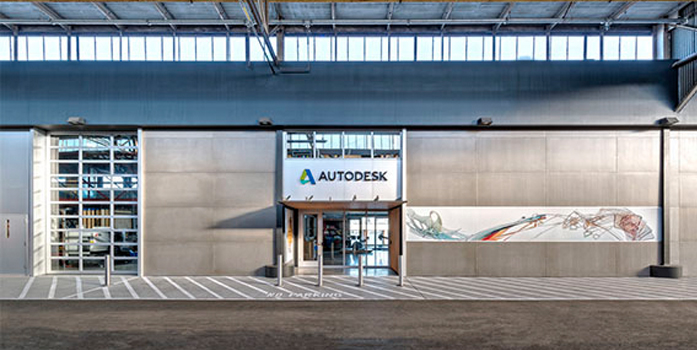

One might describe software developer Autodesk’s Workshop at Pier 9 as a traditional communal workspace. But in reality, it is a highly advanced maker space where artists, engineers, designers, architects…

Read More