Collision Sensing Terrain Follower

The OMAX Collision Sensing Terrain Follower allows a JetMachining® Center to automatically and accurately cut parts from materials with irregular or warped surfaces without the need for special programming.

The Terrain Follower attaches directly to the machine’s Z-axis. Changes in a material’s height are detected and the Z-axis automatically makes the required height adjustments, maintaining the necessary cutting standoff (typically within ± 0.020”). A collision detector pauses jet motion if obstructions are in the path of the nozzle.

For further information and orders, please contact 01257 248480.

Description

Features

- Linear encoder senses changes in material height during cutting operations

- A collision detector protects the nozzle and related hardware from damage

- Built-in containment guard minimizes nozzle splash and spray during machining

- Easy field retrofit to a Motorized Z-Axis or Tilt-A-Jet®

- Heavy duty liquid-tight electrical fitting with spring-type strain relief

- O-ring seal bulk-head air fittings with protective boots

Benefits

- Automatically maintains the correct nozzle standoff throughout the cutting process

- Adjusts automatically to uneven surfaces; reduces need for additional programming

- Constantly senses necessary height adjustments when activated, unlike other contour following products on the market

- Reduces potential equipment damage from nozzle collisions

- Simple setup and operation

- No special programming required

- No requirement to map the elevation of your material—simply move the nozzle to where you want to begin cutting and push start

- Electrical connections armoured for durability

- Robust sealing to withstand the abrasive waterjet environment

- No matter where you are located in the world, you’ll receive effective technical support to ensure your CSTF is operating at its highest levels. With hundreds of active units in the field, our technicians are strategically located to meet customer needs.

Requirements

- Microsoft Windows® Contact OMAX Customer Service for information if you are running DOS

- Motorized Z-Axis or Tilt-A-Jet

- OMAX Software version 11 or greater

Customer Reviews

At Aquajet, we take immense pride in our reputation and the glowing customer reviews. We understand that a positive reputation is built on exceptional products, outstanding service and the trust and satisfaction of our valued customers.

"I have found over the years Aquajet have always given 120% in customer service. A pleasure to do business with."

Keith Webster

"Absolutely amazing service. Very quick and professional. I will definitely be using this company again."

Phil Grant

"Brilliant service from these guys. Clean cuts precision on point. Would recommend."

Rob Carnson (Source: Facebook)

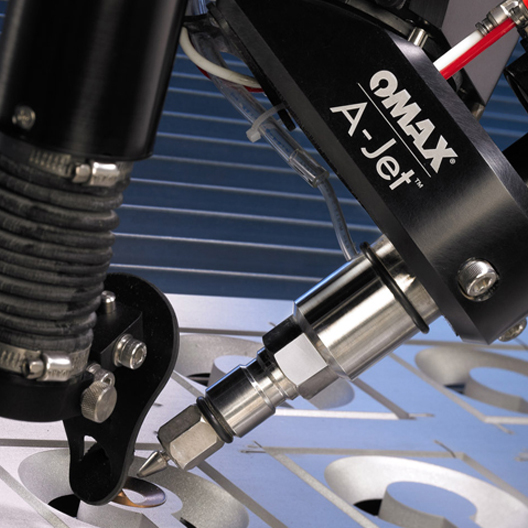

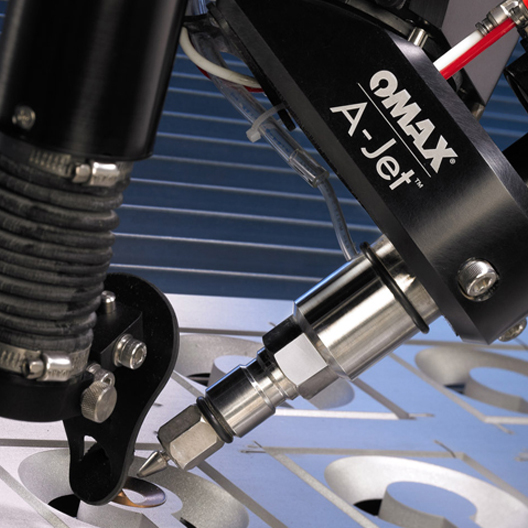

A-Jet

The patent-pending A-Jet® is a complete software-controlled, multi-axis accessory that features the flexibility to automatically compensate for taper, as well as cut severe angles up to 60° off vertical.

The A-Jet cuts countersunk holes and precision shapes with beveled edges at angles specified by the user. The accessory supplies additional axes of motion, allowing the operator to fabricate and shape metal edges for weld preparation.

The dynamic A-Jet is capable of a high level of positioning accuracy, resulting in parts that need no secondary finishing.

For further information and orders, please contact 01257 248480.

Description

Features

- High resolution magnetic encoder senses change in material height

- Automatically maintains nozzle standoff throughout the cutting process

- All electrical cabling is shielded from the abrasive waterjet environment

- Designed with robust packaging, O-ring seals, and splash guards

- All A-Jet accessories contain mounting features to add on a Terrain Follower device

- Quick and easy removal/attachment of the Terrain Follower accessory

Benefits

- Adjusts automatically to uneven surfaces, reduces need for additional programming

- Meet required tolerances and deliver competitively priced, accurate parts cut from economical, non-precision material

- Simple setup and operation

- No special programming required

- Auto standoff

- Designed specifically to operate in an abrasive waterjet environment

- Completely retrofittable to all existing A-Jet accessories

- Designed with the experience of the proven original Terrain Follower concept, which has over 200 active units in the field

- Quick and easy removal of the Terrain Follower accessory when you want extra clearance for specific jobs

Customer Reviews

At Aquajet, we take immense pride in our reputation and the glowing customer reviews. We understand that a positive reputation is built on exceptional products, outstanding service and the trust and satisfaction of our valued customers.

"I have found over the years Aquajet have always given 120% in customer service. A pleasure to do business with."

Keith Webster

"Absolutely amazing service. Very quick and professional. I will definitely be using this company again."

Phil Grant

"Brilliant service from these guys. Clean cuts precision on point. Would recommend."

Rob Carnson (Source: Facebook)