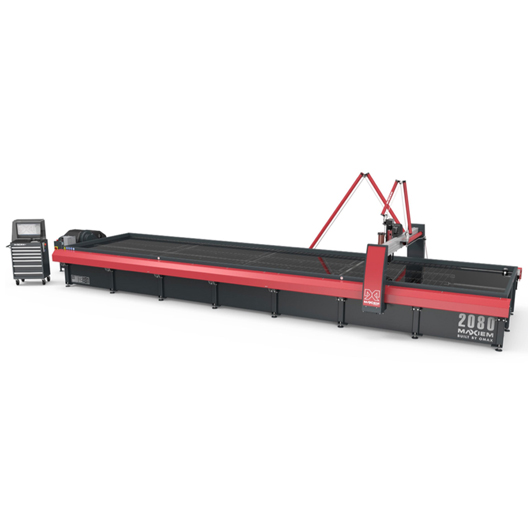

MAXIEM 2030

The next generation MAXIEM® 2030 JetMachining® Center sets a new standard for abrasive waterjet machining. Faster, smoother, and more precise, the MAXIEM 2030 is ideal for a wide range of modern machining needs.

The exclusive advanced Intelli-TRAX® digital linear encoder provides one-micron resolution instant feedback to the motor control system so the machine knows precisely where the cutting head is at all times. The mobile control station with widescreen display provides flexibility in controller positioning.

Optional accessories such as the A-Jet® for 5-axis cutting and taper compensation, Rapid Water Level Control for submerged cutting, and DualPUMP options that provide up to 80 hp of power expand your JetMachining capabilities and dramatically improve production.

For further information and orders, please contact 01257 248480.

Description

Features

- Fast cutting speeds and high precision that is backed by our exclusive Intelli-MAX® Software with real world cutting data

- Programmable Motorized Z-Axis with a precision OMAX MAXJET®5i Nozzle boosts productivity and process efficiency

- Drive system protected against water, dirt, and grit

- Powerful all-in-one controller computer with large 23” screen

- Highly efficient, industry-proven direct drive pumps available up to 40 hp with operating efficiencies up to 85%

- Free Intelli-VISOR® SE System Monitoring simplifies routine maintenance planning to minimize downtime

- Optional Rapid Water Level Control for quiet submerged cutting

- Optional Bulk Abrasive Feed Assembly transports garnet from the assembly’s large hopper into the Zero Downtime Hopper located at the Programmable Motorized Z-Axis

- Optional Variable Speed Solids Removal System (VS-SRS) designed for industrial use increases uptime through automated solids removal

- Factory tested as a complete system before shipping

Benefits

- Machines a wide range of materials and thicknesses, from metals and composites to glass and plastics

- Designed and manufactured at the OMAX factory in Kent, Washington, USA

- Does not create heat-affected zones or mechanical stresses

- No tool changes & minimal fixturing dramatically reduce setup

- Convenient controller storage drawers keep essential tools and spares close by to maintain machine uptime

- Uses substantially less cooling water than inefficient hydraulic intensifier pumps

- Small, efficient footprint for minimal floor space utilisation

- Lowest electrical consumption compared to other pump technology

- Leaves behind a satin-smooth edge, reducing secondary operations

- No noxious fumes, liquid or oils used in, or caused by, the machining process

- Environmentally “green” system uses only natural garnet abrasive and water in the cutting process

Other GlobalMAX Machines

Customer Reviews

At Aquajet, we take immense pride in our reputation and the glowing customer reviews. We understand that a positive reputation is built on exceptional products, outstanding service and the trust and satisfaction of our valued customers.

"I have found over the years Aquajet have always given 120% in customer service. A pleasure to do business with."

Keith Webster

"Absolutely amazing service. Very quick and professional. I will definitely be using this company again."

Phil Grant

"Brilliant service from these guys. Clean cuts precision on point. Would recommend."

Rob Carnson (Source: Facebook)