What is a Waterjet?

Waterjet machining has been around for decades and is one of the fastest growing machining processes today. Its ease of use and its ability to cut almost any material while maintaining high precision make it suitable for a large array of operators, from small short-run job shops and R & D facilities to large corporations engaging in full-scale production to trade schools teaching manufacturing methods.

Technology and Advantages – Flexible and Versatile

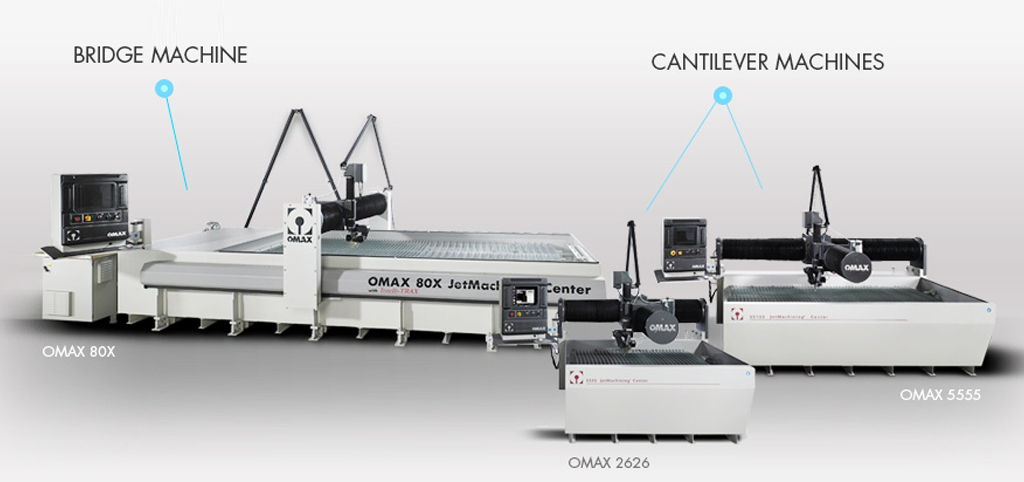

A waterjet utilises a high pressure stream of water to erode a narrow line in the stock material. To cut a wider range of materials from tool steel to titanium to foam, a granular (typically garnet) abrasive is added to the waterjet, increasing the cutting power. Because the abrasive is added at the nozzle, it is simple to switch between water only and abrasive waterjet cutting . This flexibility greatly enhances the versatility of a waterjet machine, as it can easily switch from cutting ½” (1.27cm) foam gaskets to 4” (10.16cm) titanium brackets.

OMAX Difference – Advanced Simplicity

As the nozzle moves along the material being cut, the waterjet stream will bend in the direction of travel. This means that a waterjet tends to undercut corners and swing wide on curves. Understanding the dynamics of the waterjet stream and accounting for the bend of the jet is essential for cutting quickly while maintaining accuracy. OMAX has developed extensive and accurate computer models of this flexible cutting jet in order to highly optimise the patented control software, resulting in fast, accurate cutting for all types of shapes, enabling an inexperienced operator to make accurate part without trial-and-error programming.

Customer Reviews

At Aquajet, we take immense pride in our reputation and the glowing customer reviews. We understand that a positive reputation is built on exceptional products, outstanding service and the trust and satisfaction of our valued customers.

"I have found over the years Aquajet have always given 120% in customer service. A pleasure to do business with."

Keith Webster

"Absolutely amazing service. Very quick and professional. I will definitely be using this company again."

Phil Grant

"Brilliant service from these guys. Clean cuts precision on point. Would recommend."

Rob Carnson (Source: Facebook)